3D Printing for Jewelry Manufacturing

UNLEASH DESIGN FREEDOM AND INCREASE QUALITY FOR HIGH-VOLUME PRODUCTION AND CUSTOM JEWELRY

3D Printing Experience to Meet Your Jewelry Production Needs

Successful jewelry design requires creativity and quality. We combine over 20 years of jewelry manufacturing experience and industry-specific solutions to give you a competitive advantage in high-throughput and mass-custom jewelry manufacturing.

Our 3D printing solutions ensure perfect quality and reliability every time, reduce time to market and cost, and, while fitting into your standard manufacturing workflows, allow you to achieve new levels of jewelry design and productivity.

.png)

The Role of 3D Printing in Jewellery Manufacturing

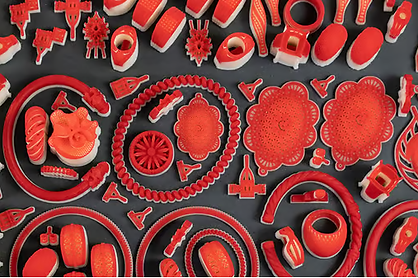

Reveal your most creative jewelry designs faster and increase productivity without compromising quality. Our solutions for 3D printed jewelry casting patterns fit with your standard process for reliable output every time, bringing you maximum design freedom for high-volume and mass custom jewelry manufacturing.

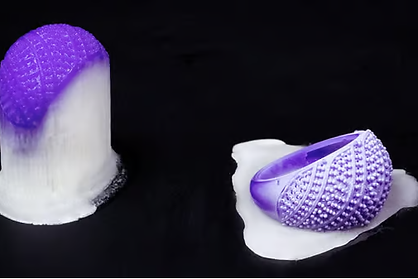

Leverage 3D Systems solutions developed for compatibility with jewelry mold making processes for high-volume manufacturing. 3D print ultra-high-detail, heat-resistant, high-quality, complex master patterns to create your rubber mold in a matter of hours.

Accelerate creativity with accurate, finely detailed, high-fidelity prototypes. Our solutions provide a quick turnaround from digital designs to 3D printed jewelry models, allowing for fast design iteration, validation, stone settings, and try-on.

Addressing All Your Jewelry Design Challenges with 3D Printing

Every jewelry style has its own design and production challenges. Our 3D jewelry manufacturing solutions provide a competitive advantage, with the high quality, accuracy, and reliability required for every design style.

Middle Eastern / Arabic

With features such as thin wires, twisted pipes, and ornate surfaces, sharpness and fine details are critical. Our 3D printing solutions for prototyping, casting and rubber moulding patterns deliver high-resolution and fine details down to 0.2 mm.

Fusion

These designs require the ability to produce hollow, lightweight filigree and thin wire mesh shapes. Our solutions for castable plastic or 100% wax pattern production deliver the capabilities required for these highly detailed pieces.

Pavé and Stone Setting

Single, multiple, and pavé stone designs—some including micro-prongs with gaps as small as 0.2 mm—require accurate patterns and a superior surface finish. From functional prototyping and stone setting validation, to patterns for direct casting or rubber molding, our 3D jewelry printing solutions deliver parts with the high accuracy, smooth finish, and fine details required for even the smallest prongs.

Western

These solid, heavier-weight designs feature a large surface area that requires patterns with a smooth surface finish. From prototyping for design validation to 3D printed patterns for direct casting and rubber molding, our 3D solutions generate geometries that fit into your manufacturing process seamlessly.

Design Optimization

Dramatically boost carbon capture systems’ performance and efficiency leveraging the design optimization capability of 3D printing. Peak efficiency means there is no energy loss in system operation which translates to a lower cost per ton.

Long Service Life

Metal 3D printed components are made for reliability and extensive service life. 3D print using a range of alloys that are high temperature and corrosion-resistant while possessing high thermal conductivity.

Speed of Iteration

True design iteration and practical tests to find the ideal design solution faster is crucial. Our 3D printing solutions offer rapid prototyping capabilities, so you validate and get to the final, optimum design faster.

Scalability

Not only accelerating the development of cost-effective and energy-efficient new technologies, these innovative solutions also become rapidly available via scalable additive manufacturing to support the massive need in the field for equipment.

Supply Chain Efficiencies

Part consolidation and monolithic design capabilities enable quality and streamlining of the supply chain. Eliminate the carbon footprint of using multiple suppliers across the country to produce a single assembly.

Expert Consultancy

Partner with us to develop new concepts and solutions, and quickly scale to production volumes. We provide full support to address our customers' challenges and help establish your own additive manufacturing capabilities.