Productive and Cost-Effective Digital Manufacturing Solutions

Our DLP platform - Figure 4, delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

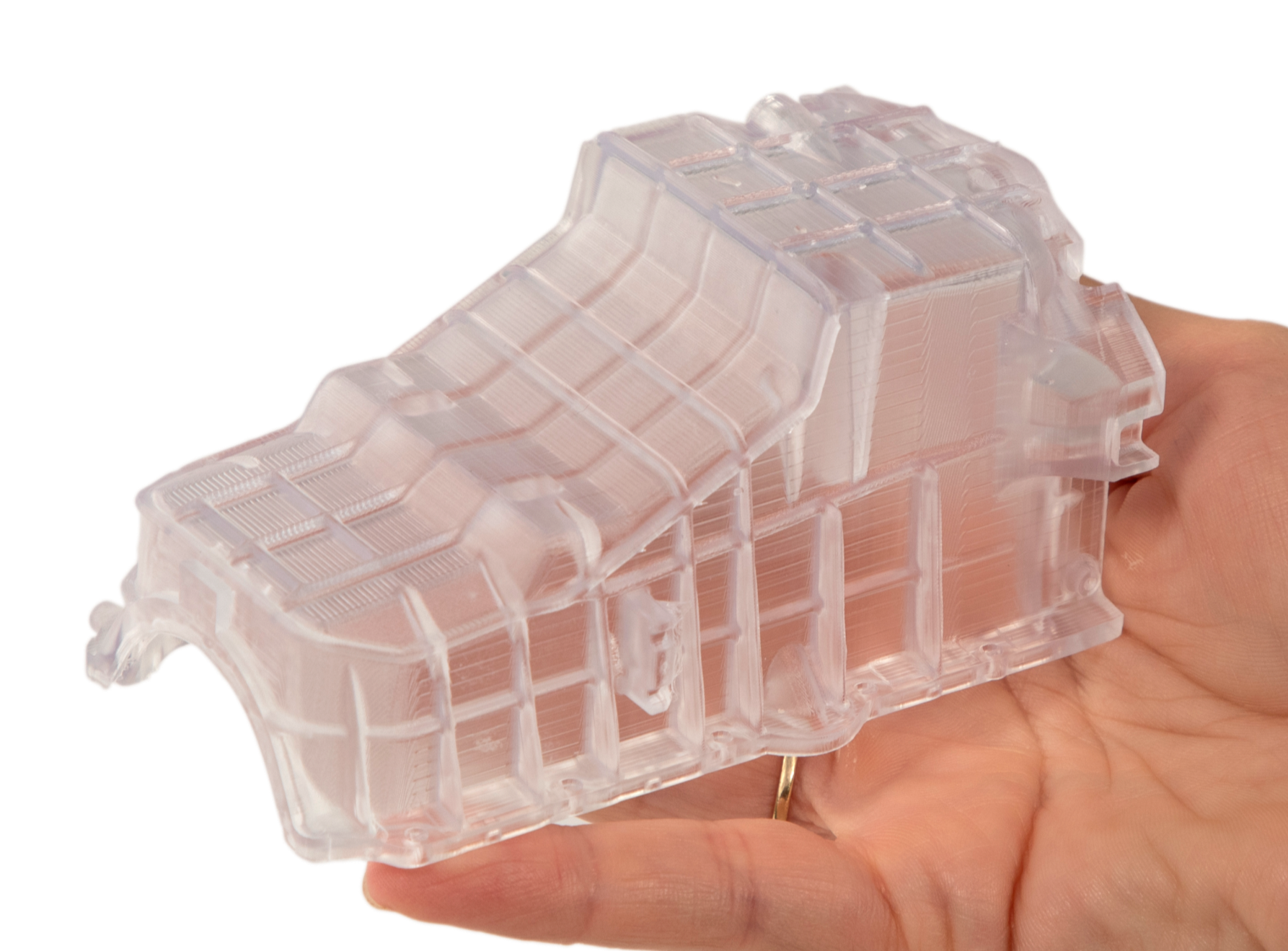

Figure 4 delivers ultra-fast additive manufacturing technology with systems that offer expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts. Get the quality and performance of injection-molded parts with smooth surface finish and exceptional sidewall quality, without the time or cost of tooling.

High Speed Direct Digital Production

3D Systems Figure 4 makes 3D production a reality—with increased productivity, durability, repeatability and lower total cost of operations (TCO). Figure 4 delivers productivity enabled through speed and automation with real world repeatable, accurate parts with demonstrated Six Sigma performance in a diverse range of robust, production-grade materials.

Manufacturing Redefined

Broad Range of Materials

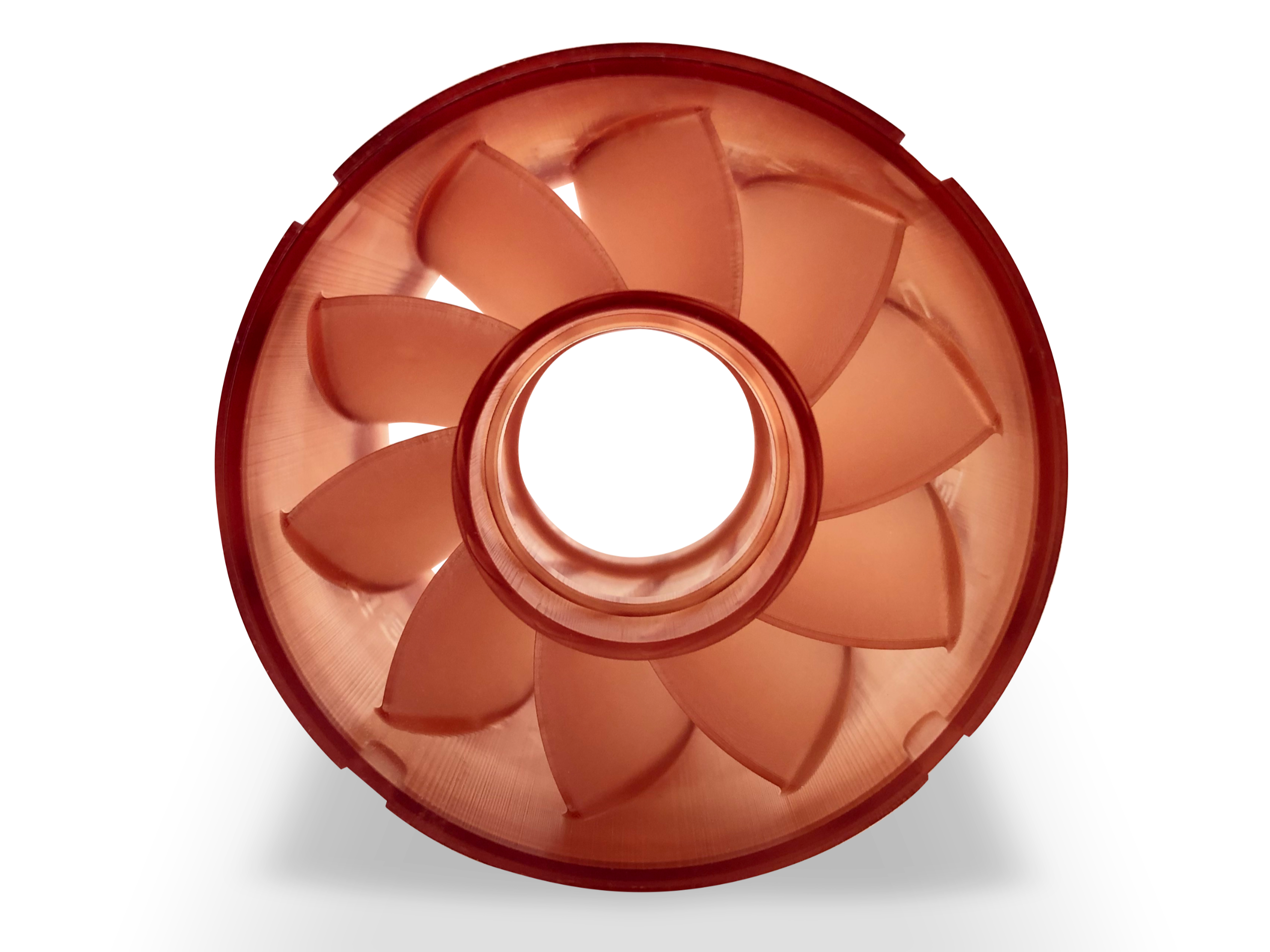

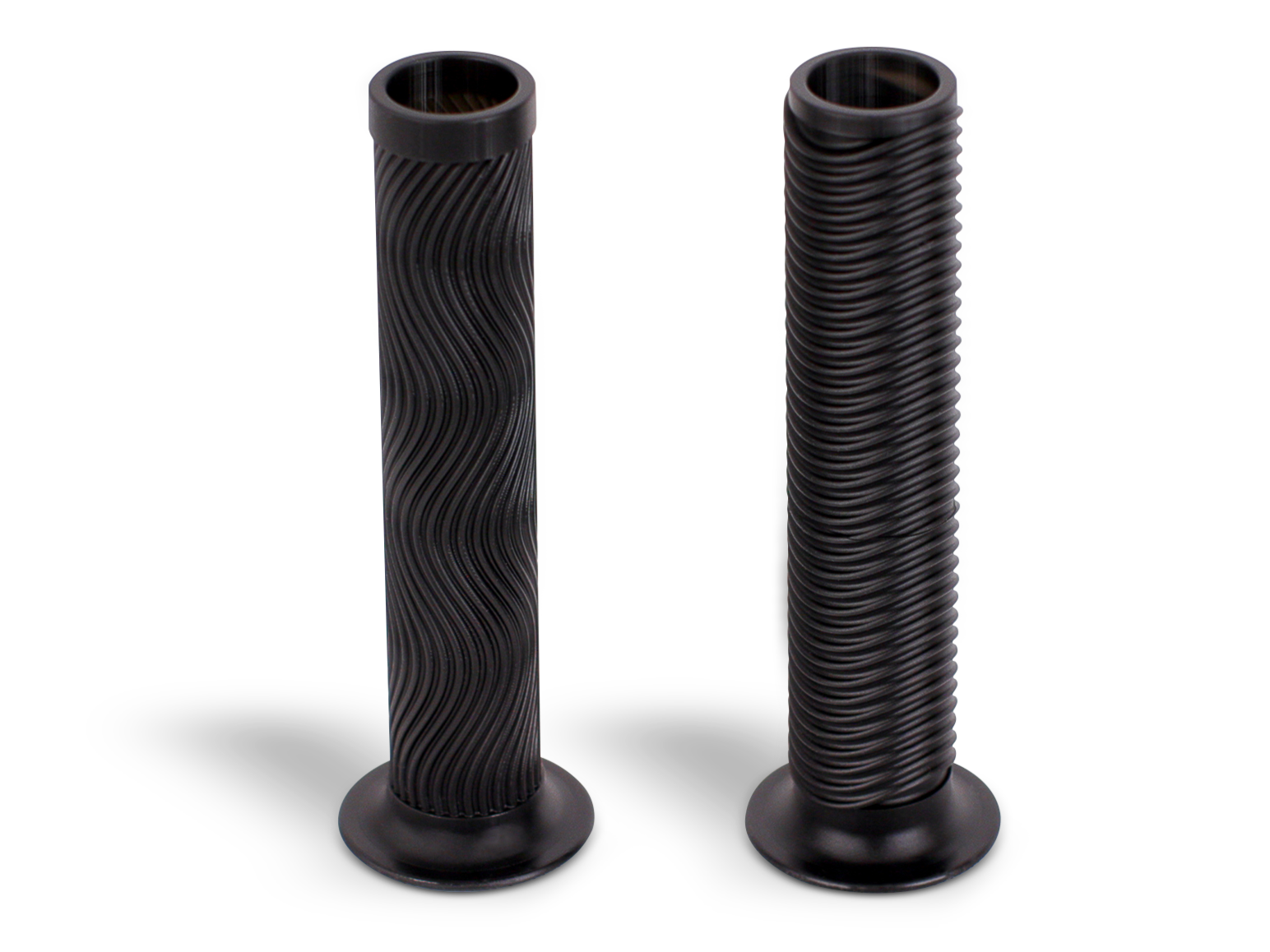

The broad and expanding range of materials available for Figure 4 platform addresses a wide variety of applications needs, for functional prototyping, direct production of end-use parts, moulding and casting, and includes rigid and durable with thermoplastic-like behaviours, rubber-like, castable, heat resistant, and biocompatible capable materials.

Materials for Variety of Applications

From functional prototyping, production grade end-use parts, moulding and casting, rigid and durable, rubber-like, castable, heat resistant, and biocompatible capable materials.

Production Grade

Production-grade, rigid material for production parts.

Long-term use parts with a good combination of impact strength, elongation, and tensile strength.

Rubber, Flex & Elastomeric

High stability, durable and flexible plastic. Mid tear strength production-grade rubber.

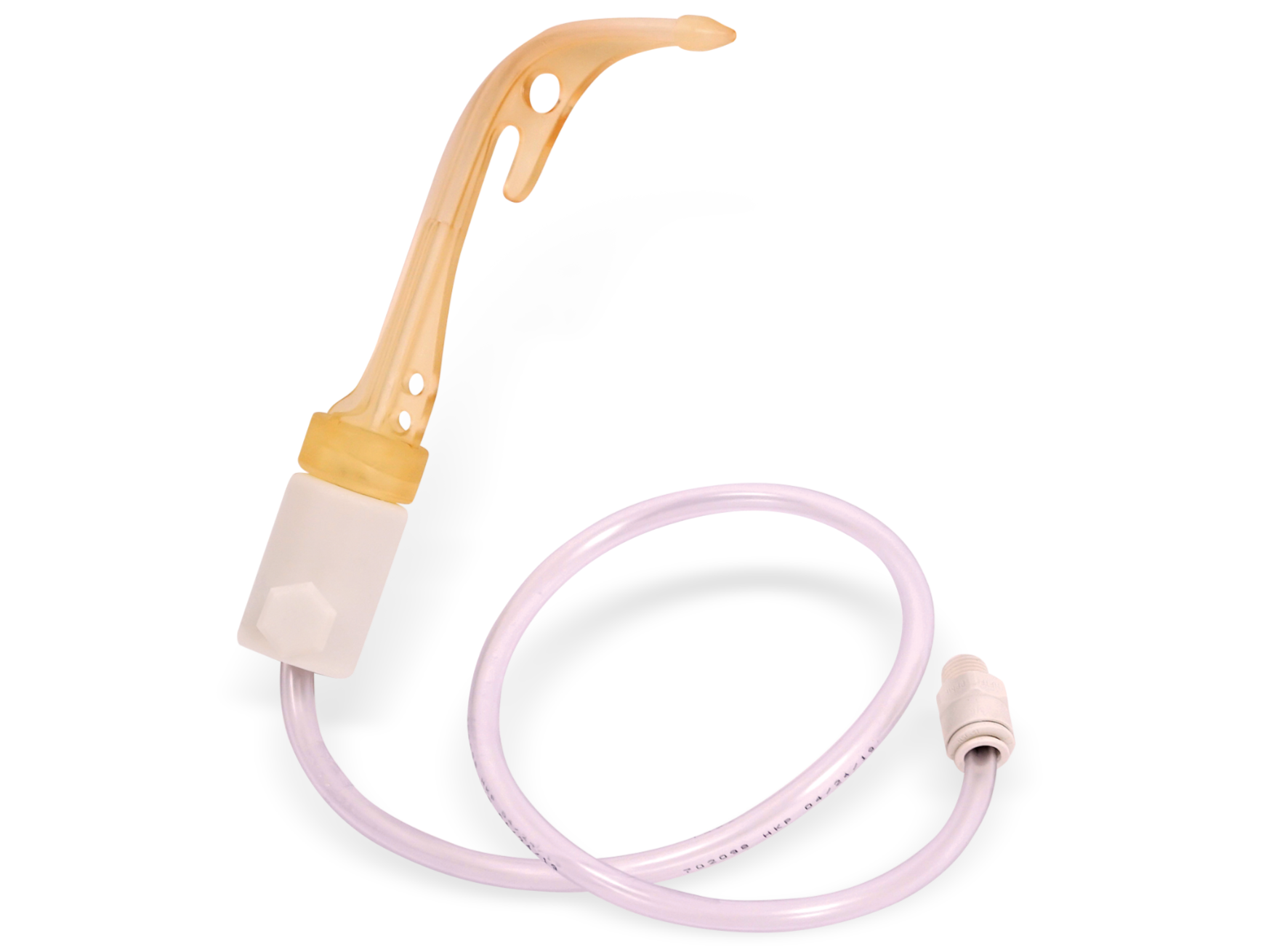

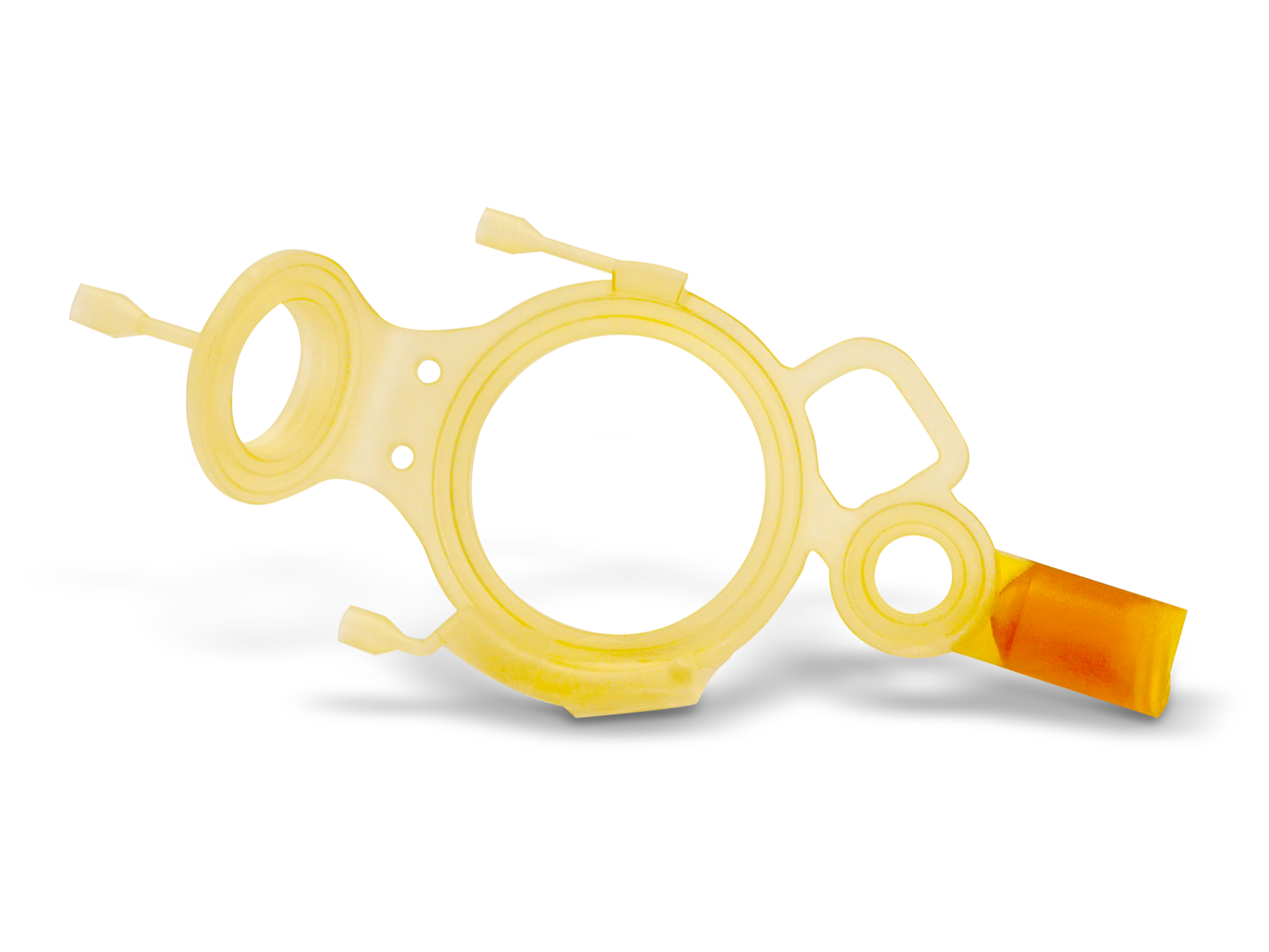

Biocompatible

Rigid, translucent material that can be sterilized and tested at high temperature.

Jewellery Solutions

Castable material & master patterns for high-resolution patterns.

Sacrificial Tooling

Process-optimized material for sacrificial tooling to cast silicone.

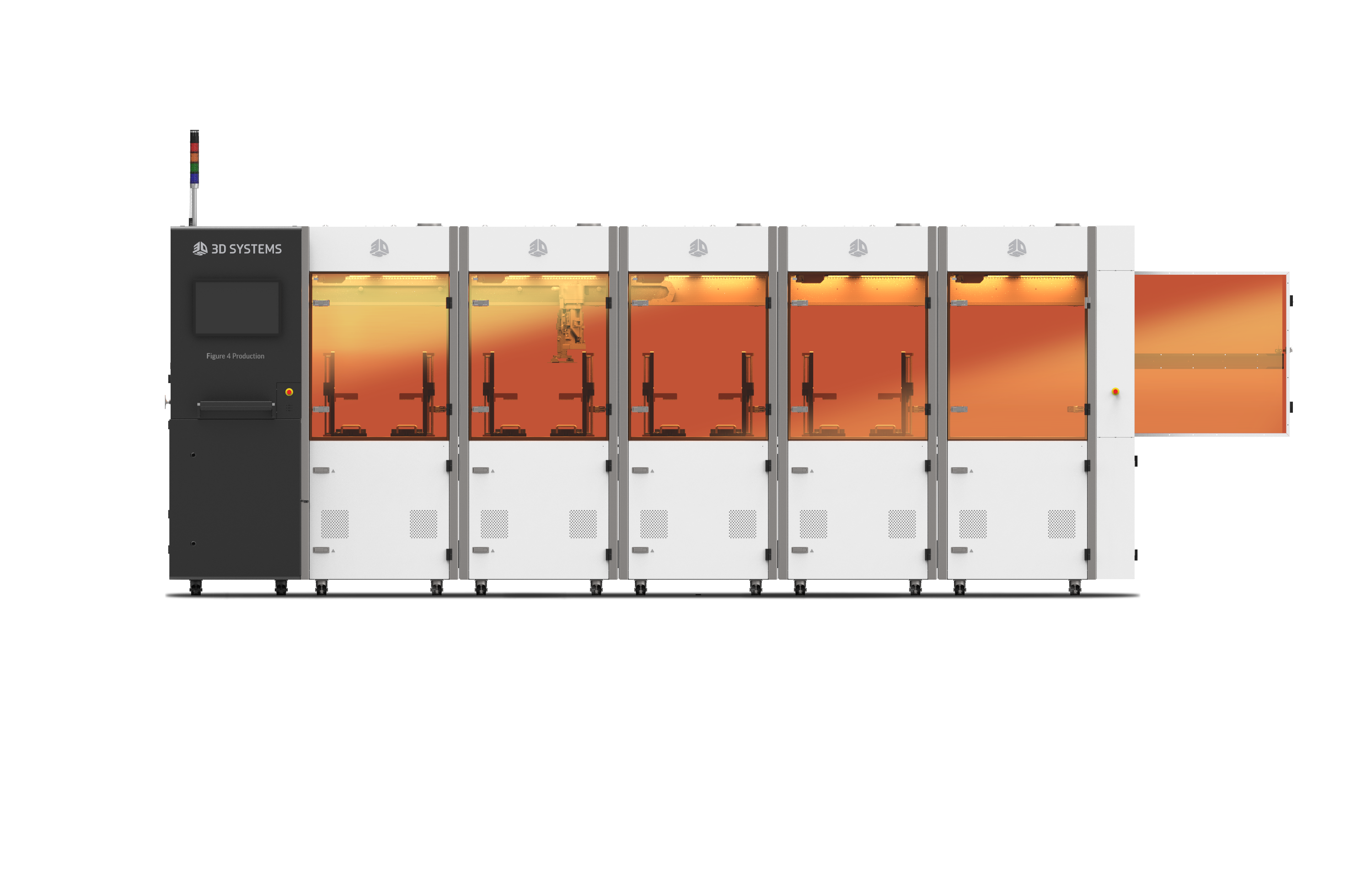

Modular Platform Grows with Manufacturing Needs

Delivered in configurable units for anytime scalability, Figure 4 allows manufacturing capacity to grow alongside demand – from a standalone printer for rapid prototyping and low volume direct 3D production, to modular systems that grow as your volume grows, up to a fully-automated, fully-integrated factory solution.

Print Engine Cell

Print Engine Cell

Print Engine Cell

Print Engine Cell

Control Cell

DLP Printers

Our MJP materials include a wide range of functional, precision plastics, elastomeric, multi-material composites, and wax, enabling a broad set of applications for concept modelling, functional prototyping, rapid tooling, investment casting, and medical applications requiring biocompatibility.

Affordable and versatile for low-volume production and fast prototyping, offering quality and accuracy with industrial-grade durability, service and support.

Affordable and versatile

Same-day prototyping and direct 3D production up to 10,000 parts per month. In addition, each printer can run different materials and different jobs as part of a single high throughput line serving a multitude of parts being produced.

Speed and versatility

Scalable, semi-automated 3D manufacturing solution designed to grow with your prototyping and production needs. Enabling companies to move directly into production from digital CAD files to delivering final parts immediately.

Revolutionizing manufacturing

Combines the design flexibility of additive manufacturing in configurable, in-line production cells to deliver a customizable and automated direct 3D production solution.

Flexible To Fit Your Needs

Produce 1 million+ parts per year in a broad range of industrial, dental and custom materials.

Manufacturing At Scale

Figure 4 Production

Capable of creating prints ready for prototyping, casting, or moulding in hours, Figure 4 Jewellery enables manufacturing to accelerate time-to-market and quickly respond to market demands for custom jewellery or short-run production at low per piece cost. Figure 4 Jewellery's fast, digital workflow is responsive to any design modification, whether minor or drastic, so new designs can be delivered within very short timeframes, enabling unparalleled flexibility.

Faster Time-To-Market

Figure 4 Jewellery