MJP - MultiJet 3D Printing

MJP Applications

Precision Plastic, Elastomeric, Wax and Composite Parts

-

Biocompatible medical devices requiring USP Class VI and/or ISO 10993 capability

-

Jigs, fixtures, and tools

-

Patterns, dies, and molds for rapid tooling

-

Investment casting patterns production for industrial applications

-

Investment casting patterns production for jewelry applications

General

-

Communication, sales, and marketing models

-

Rapid design iteration for rigid plastic or elastomeric products

Concept modelling

-

Design verification and testing

-

Assemblies validation, including snap-fits and multi-material assemblies

-

Water-tight applications, fluid flow visualization

-

Functional testing of plastic and elastomeric products

-

Over-moulding

Validation prototyping

Office compatibility is another benefit of MJP printers, offering convenient and affordable access to high-quality prototypes and indirect manufacturing aids. MJP printers are ideal for direct investment casting applications in jewelry, dental, medical, and aerospace applications where digital workflows provide significant time, labor, quality, and cost advantages. MJP wax printers also offer a digital alternative to traditional lost-wax casting processes, eliminating time consuming and costly processes while integrating seamlessly with traditional casting methods and materials.

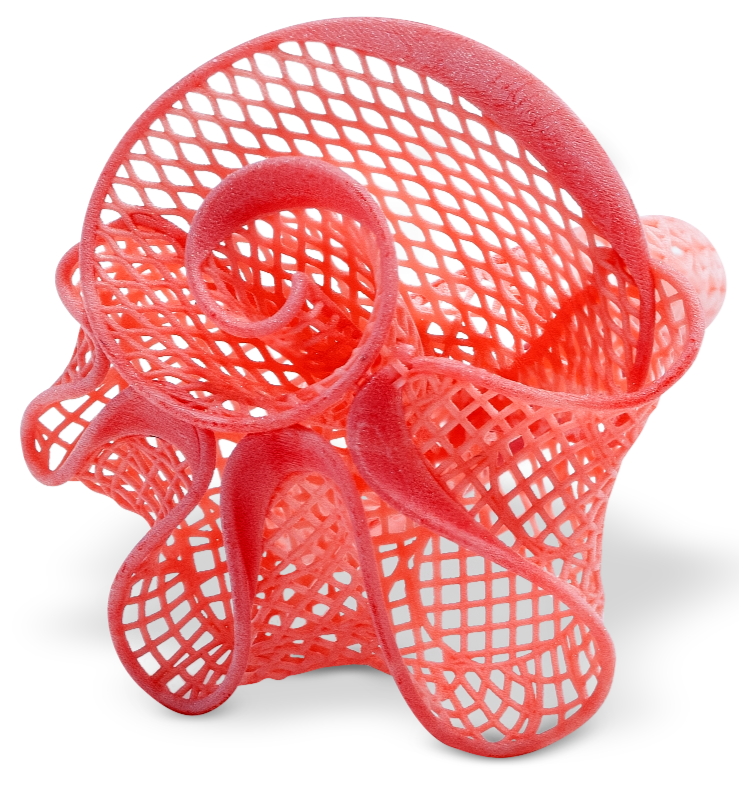

MultiJet Printing (MJP) is an inkjet printing process that uses piezo printhead technology to deposit either photocurable plastic resin or casting wax materials, layer-by-layer. MJP is used to build parts, patterns, and molds with fine feature detail to address a wide range of applications. These high-resolution printers are economical to own and operate, and use a meltable or dissolvable support material to simplify post-processing. This also makes support removal virtually a hands-free and allows even the most delicate features and complex internal cavities to be thoroughly cleaned without damage.

MJP printers provide quick turnaround on smooth, high-resolution, hard plastic parts with complex geometries. The printing process consists of UV bulbs and photopolymer materials. MJP printers offer the highest Z-direction resolution with layer thicknesses as low as 16 microns. Selectable print modes allow users to choose the best combination of resolution and print speed, making it easy to find a combination that matches the needs of the application. MJP parts have a smooth surface finish and can achieve accuracies rivaling SLA for many applications. Recent material advances have improved the durability of plastic materials making them suitable for some end-use applications.

MultiJet Printing (MJP) technology produces high fidelity, true-to-CAD parts, with fast print times, easy operation and simple post-processing for high productivity and true simplicity, from file to finished part. The wide range of VisiJet materials for the ProJet MJP Series enables a broad set of applications for concept modelling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, casting patterns and medical applications requiring USP Class VI and/or ISO 10993 certification.

MJP Material Properties & Uses

Our MJP materials include a wide range of functional, precision plastics, elastomeric, multi-material composites, and wax, enabling a broad set of applications for concept modelling, functional prototyping, rapid tooling, investment casting, and medical applications requiring biocompatibility.

Developed to bring enhanced durability and strength to MJP printing, these materials include options to simulate ABS or polypropylene to deliver the material properties you need.

For MJP parts that look and feel like injection-moulded parts, available in a variety of colours from white, black, clear, to grey and tan.

High elongation and Shore A hardness make these materials great for MJP prototypes with rubber like functionality.

Print parts in single or several base materials, or mix multiple rigid and elastomeric materials to achieve custom performance characteristics

Wax

Get the same melt and burn-out characteristics of standard casting waxes with VisiJet 100% wax 3D printing materials.

MJP Printers

Our MJP materials include a wide range of functional, precision plastics, elastomeric, multi-material composites, and wax, enabling a broad set of applications for concept modelling, functional prototyping, rapid tooling, investment casting, and medical applications requiring biocompatibility.

-

Up to 3x higher 3D printing speeds than similar class printers and finished part delivery up to 4x faster with 3D Systems MJP EasyClean System

-

Capable of printing in rigid, engineering-grade, high temperature resistant, elastomeric or biocompatible materials, in clear or in a range of opaque colours

-

Perfect for concept modelling, rapid design iteration and validation, jigs and fixtures, patterns and moulds

MultiJet printing quality, speed and ease of use made accessible

Projet MJP 2500P (Polymer)

-

100% wax casting reliability

-

High fidelity patterns with exceptional sharp edges, fine feature definition and smooth surfaces

-

Greater geometric freedom with dissolvable and meltable supports

-

For high-volume and mass custom jewellery manufacturing

-

From fast turnaround short runs to high volume production

High productivity and affordability for 100% wax jewelry casting patterns

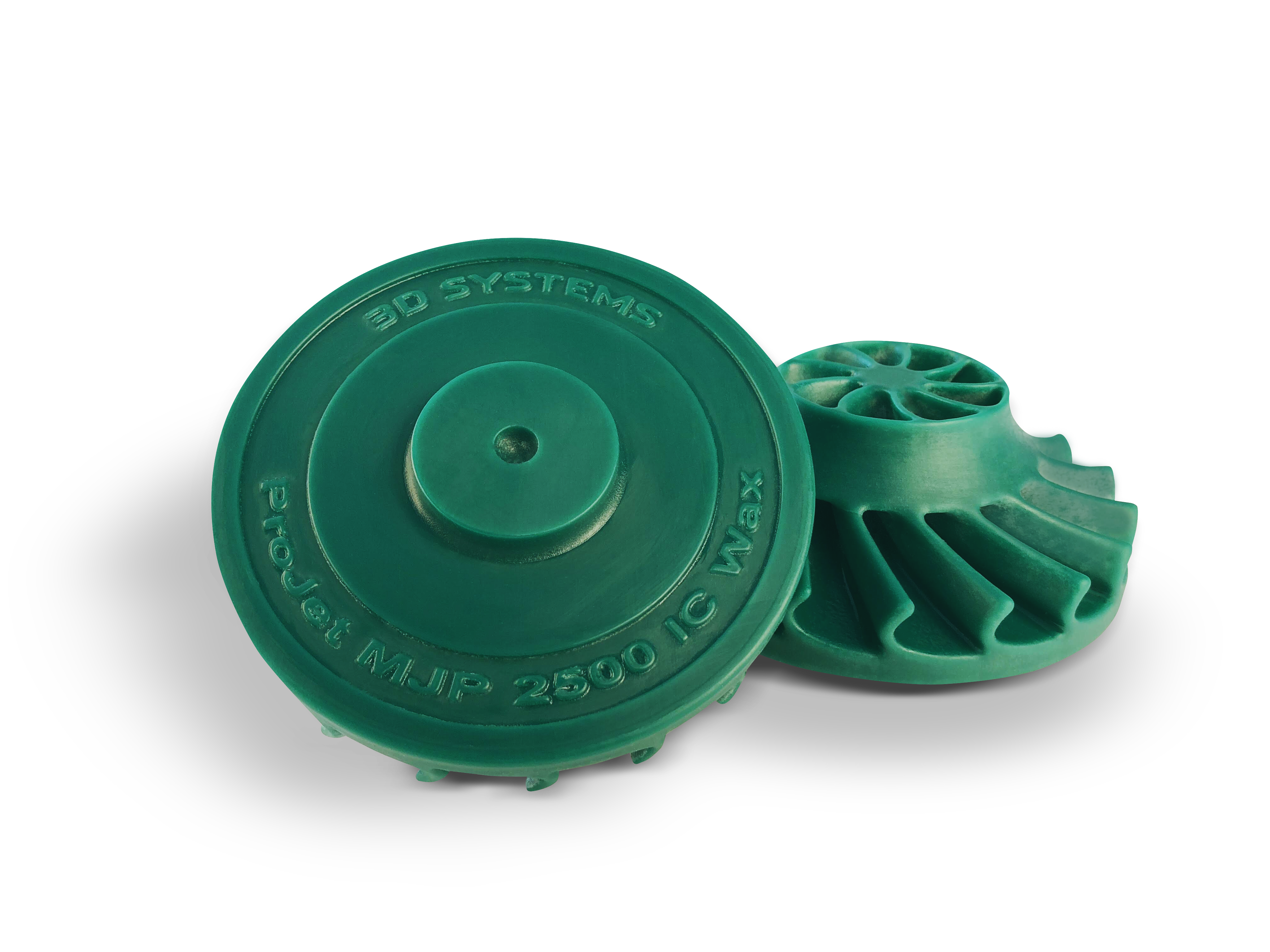

Projet MJP 2500W Plus

-

High quality small to mid-sized wax patterns that fit directly into a standard foundry casting process

-

Ideal for customized metal components, bridge manufacturing and low volume production

-

VisiJet® M2 ICast 100% wax material delivers the same melt and burn-out characteristics of standard casting waxes

Tool-less production of 100% wax casting patterns

Projet MJP 2500IC

-

Produce over-molded parts, multi-material assemblies, rubber-like components, jigs and fixtures, dies and more.

-

Five base materials: rigid white, black or clear, elastomeric black or natural, plus more than 100 composite combinations

-

Print parts up to half a meter long or several smaller parts in a single build

Large format, multi-material composite parts in a single build

Projet MJP 5600

-

100% wax casting reliability

-

4 printing modes to match the level of speed, geometric complexity and surface quality your designs require

-

Greater geometric freedom with superior resolution and dissolvable/meltable supports

-

For high-volume and mass custom jewellery manufacturing

-

From fast turnaround short runs to high volume production

Flexibile, fast, and high-quality jewelry wax patterns 3D printer

Projet MJP 300W