-

Producing complex parts that cannot be made using traditional methods

-

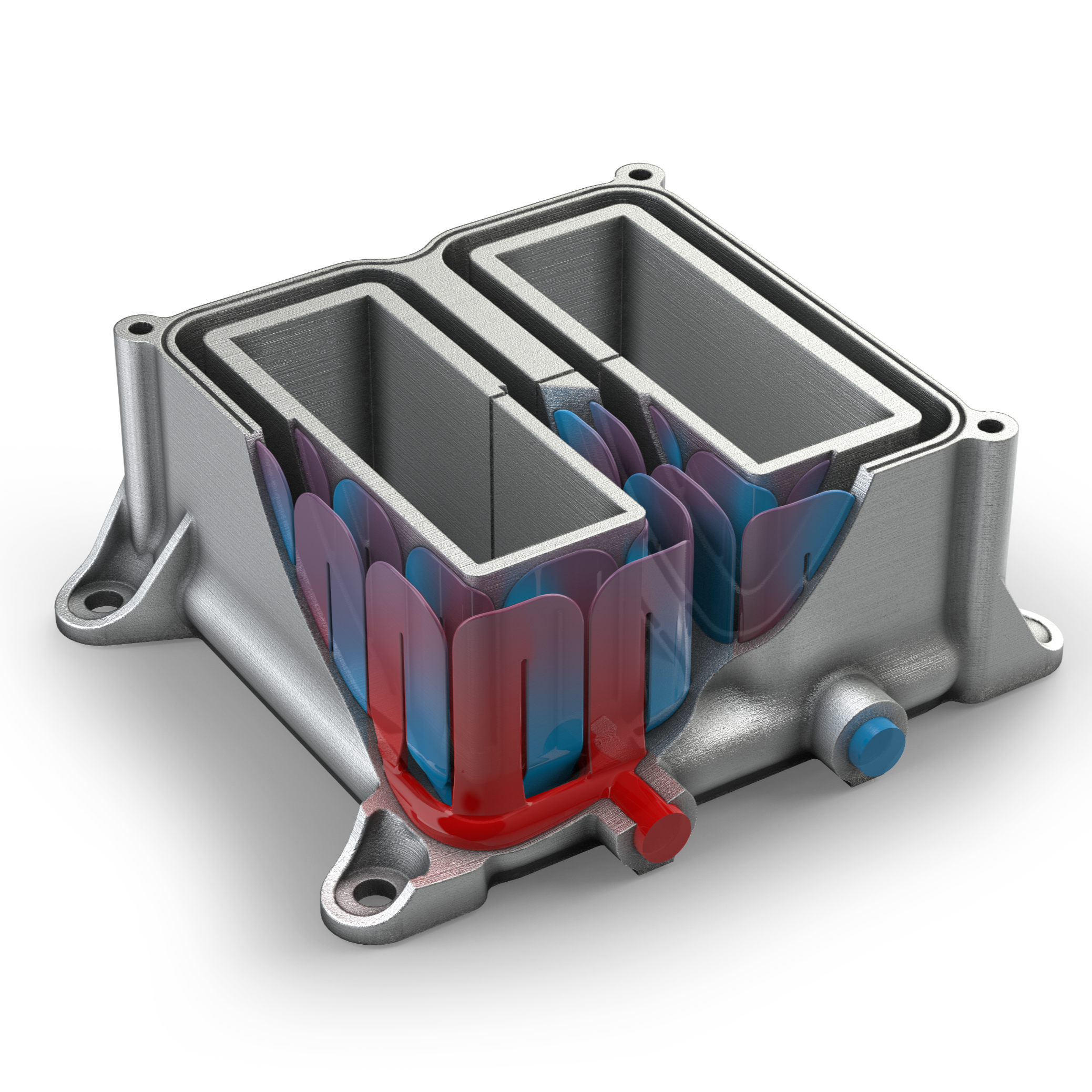

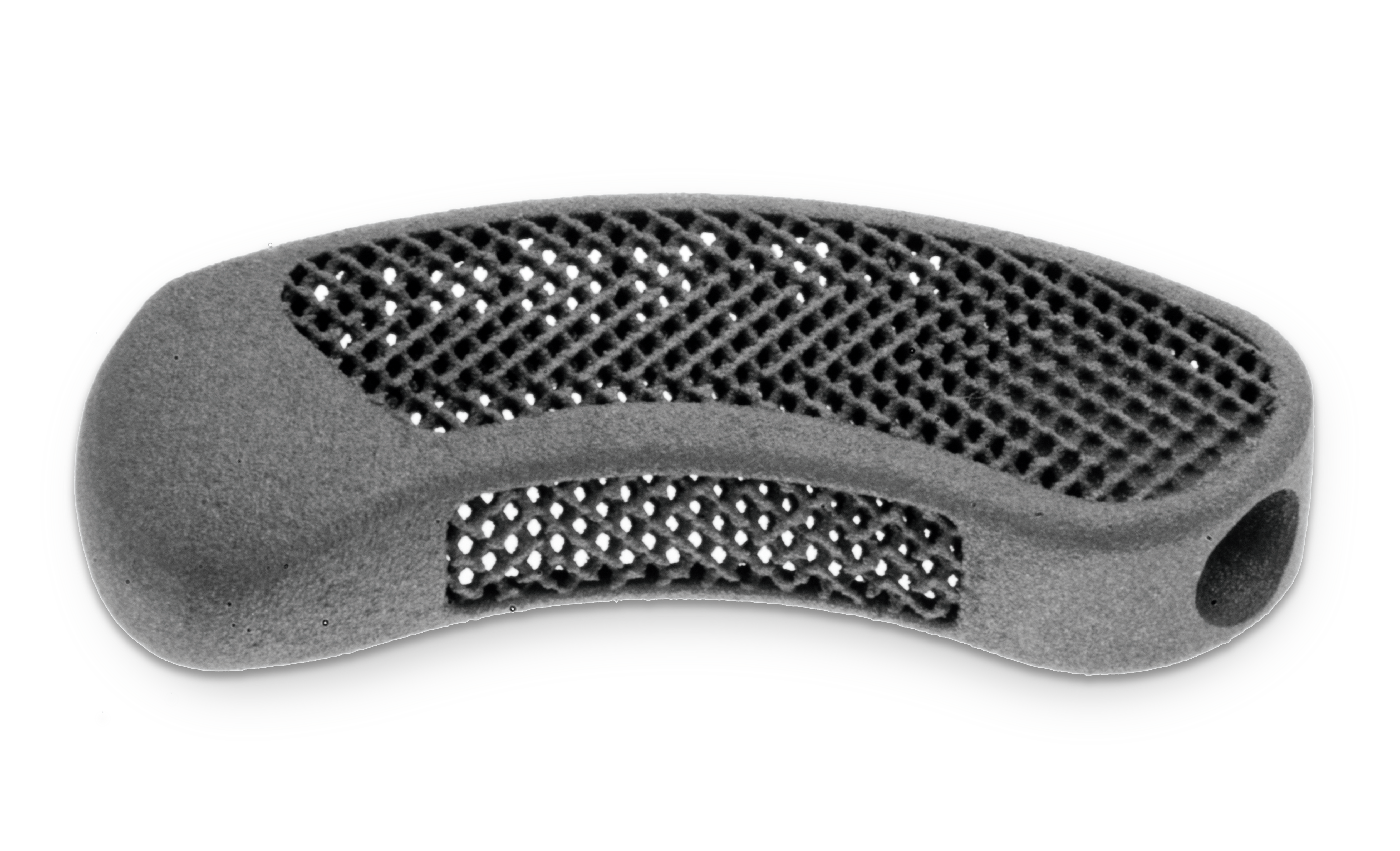

Conformal cooling channels and latticework

-

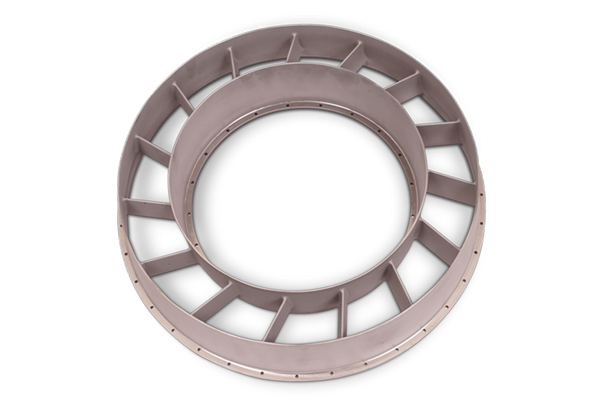

Enhanced fluid flow

-

Direct tool-free production of injection molding inserts and cores

-

Mass personal customization of orthopedic, dental, and other parts

-

Parts with cavities, undercuts. and draft angles

-

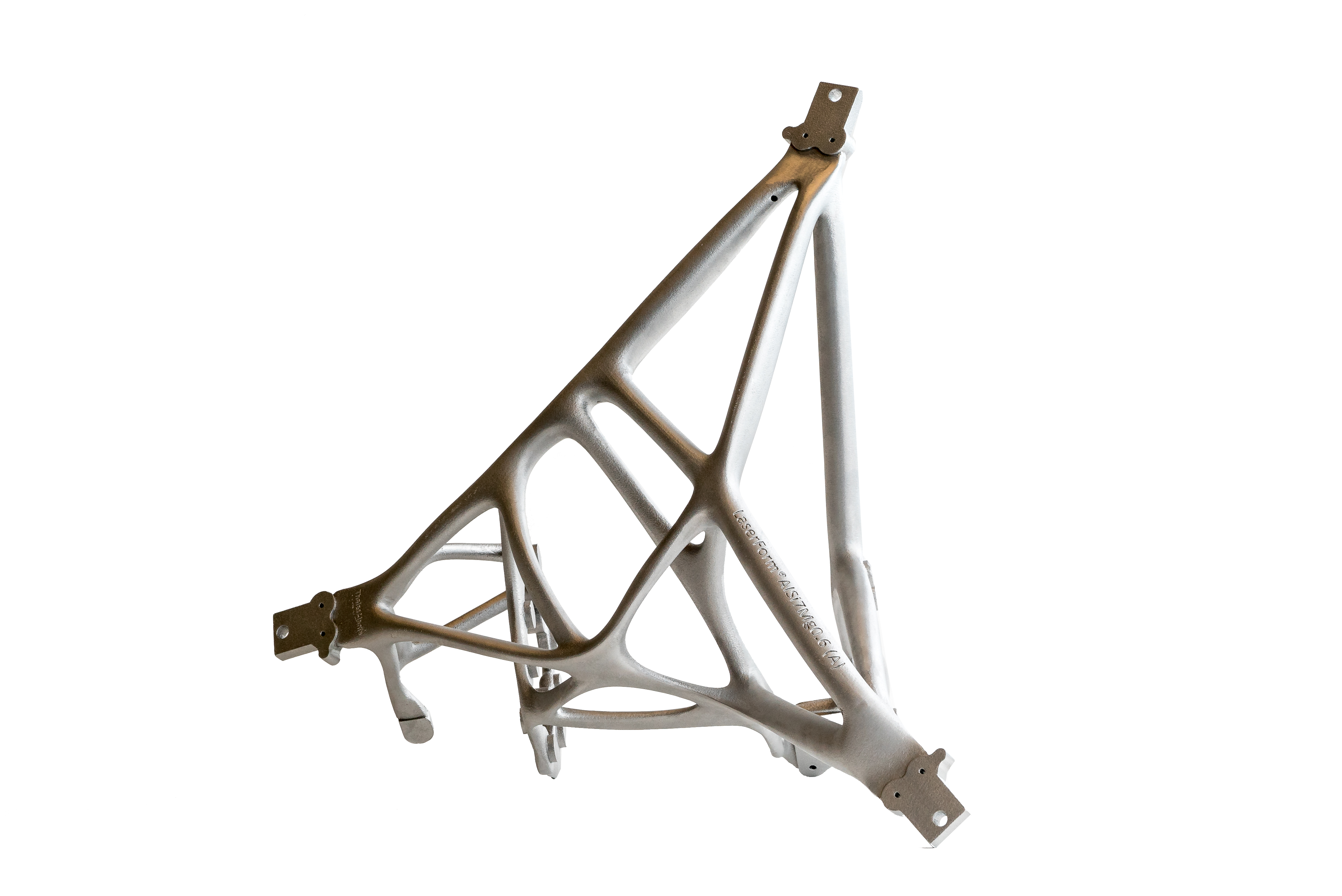

Reduced-weight and light-weight design

-

Research and development

-

Simplified assemblies and part consolidation

-

Small, precision parts production

-

Topology optimization while maintaining structural integrity

Our DMP printers allow you to create metal parts while achieving fine detail, which is why DMP is perfect for a variety of applications.

This includes, but is not limited to:

Direct Metal Printing gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. DMP allow designers and manufacturers to design, test and produce metal parts that are simply not possible to create with standard manufacturing techniques. This cutting edge technology allows for the production of metal parts with challenging geometries, not possible using traditional subtractive or casting technologies. A variety of functional metals are available to print designs, from prototypes to production series of up to 20,000 units.

DMP is a powerful 3D printing technology that shapes any desired metal part geometry by melting metal powder layer by layer. This technology is applied to build up material in layers instead of removing it in different steps. The metal powder particles pinpointed by the laser quickly and fully melt so that the new material properly attaches to the previous layer, without glue or binder liquid. A powerful fiber laser with high energy intensity operates in the inert area inside the machine. This guarantees that the metal parts being built exhibit a dense and homogenous material structure. The CAD design of the parts directly drives the DMP production machines without the need for programming, clamping or tooling.

DMP Material Properties & Uses

A combination of high strength, low weight and excellent biocompatibility define Titanium alloys. When metal 3d printing it is critical for final part quality as well as for the total cost of operation (TCO) that the highly reactive titanium powder is not exposed to oxygen. You need vacuum chamber architecture to keep oxygen exposure under 25ppm during the entire print build. This ensures consistent part properties and nearly 100% powder usage.

Titanium Alloys

Good for complex metal 3d printed parts with excellent strength, high ductility, wear and corrosion resistance. Stainless steel parts can be easily welded, CNC machined, spark eroded and polished - integrating conventional manufacturing processes with metal AM. Stainless steel parts produced with DMP/PBF/DMLS/SLM are typically used for machine components, food-safe applications, medical devices and surgical instruments. Steel alloys are often used for spare part production. Select alloys with thoroughly developed and tested print parameters.

Stainless Steel Alloys

Use genuine tool steel (1.2709) for the direct production of tools, molds and high-performance parts that require high strength and hardness. Metal 3D printing enables direct inclusion of conformal cooling channels for improved head management in injection molding tools, enabling shorter cycle times and longer tool lifetime. Shows good weldability and machinability for post-processing and integration of additive with conventional technologies for a reduced total cost. Available with thoroughly developed and tested print parameters.

Maraging Steel Alloys

Used for highly corrosion-and wear resistant industrial parts that require high-temperature resistance. Can be used for reducing weight, improving fluid flow and consolidating parts for turbine and engine components, design and watchmaking products, parts with thin walls or fine features and mechanical components needing wear and corrosion resistance. Available with thoroughly developed and tested print parameters.

Cobalt Chromium Alloy – For Industrial and Dental use

The potential for weight reduction through part design is a big benefit In metal 3D printing, Aluminum alloys are often used for light-weight, high strength applications in automotive, aerospace & machinery. Innovative applications such as mold design and specific heat exchanger applications make use of the high thermal conductivity of specific aluminum alloys. Available with thoroughly developed and tested print parameters.

Aluminium Alloys

DMP Printers

Rethink metal part design and produce products, components and tools with reduced weight, increased functionalities and simplified assemblies.

-

Build volume 100 x 100 x 90 mm

-

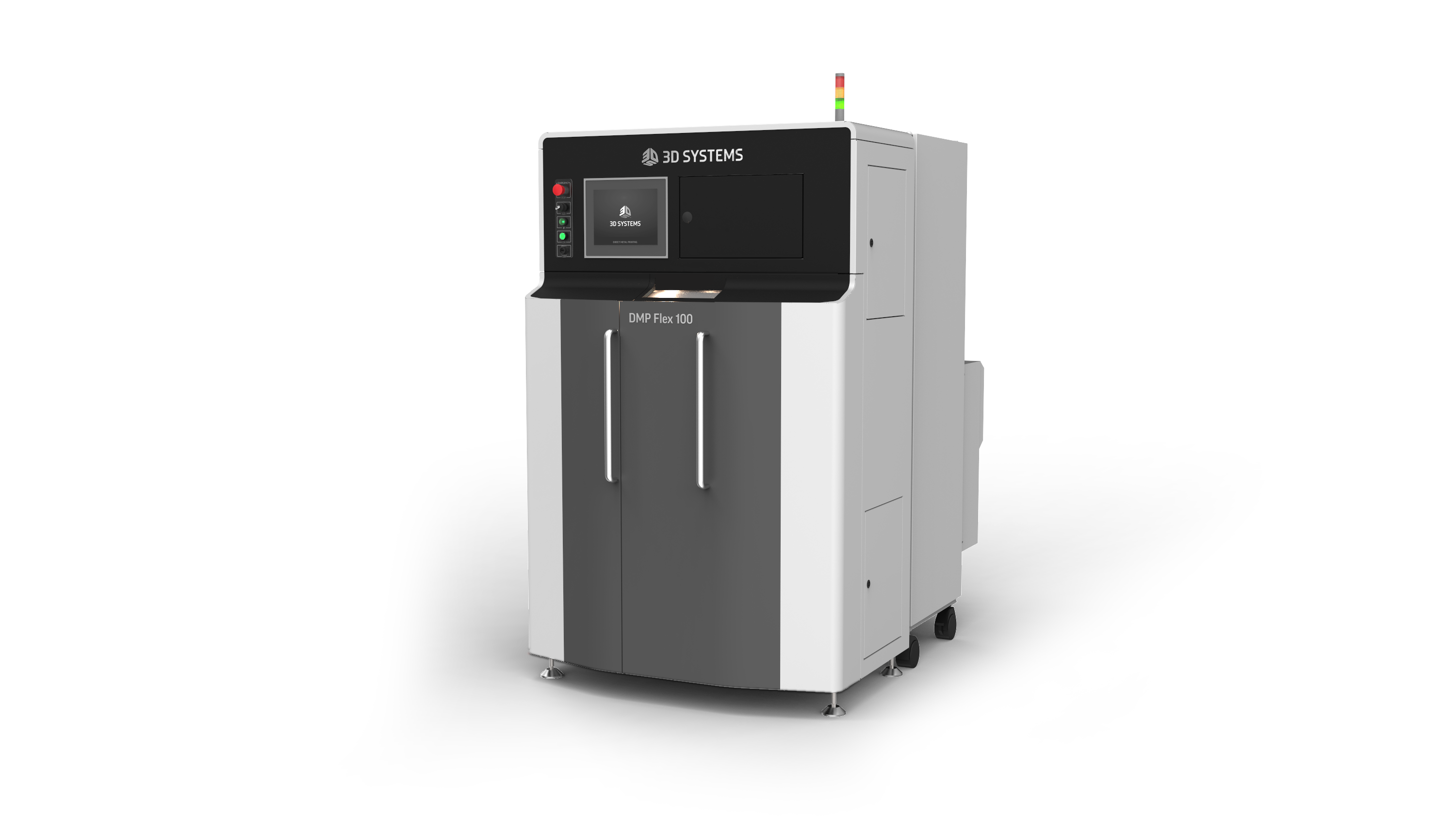

Entry-level metal printer

-

Fine features, thin walls

-

Best in class surface finish

Affordable, precise metal 3D printer for finest features and thinnest walls

-

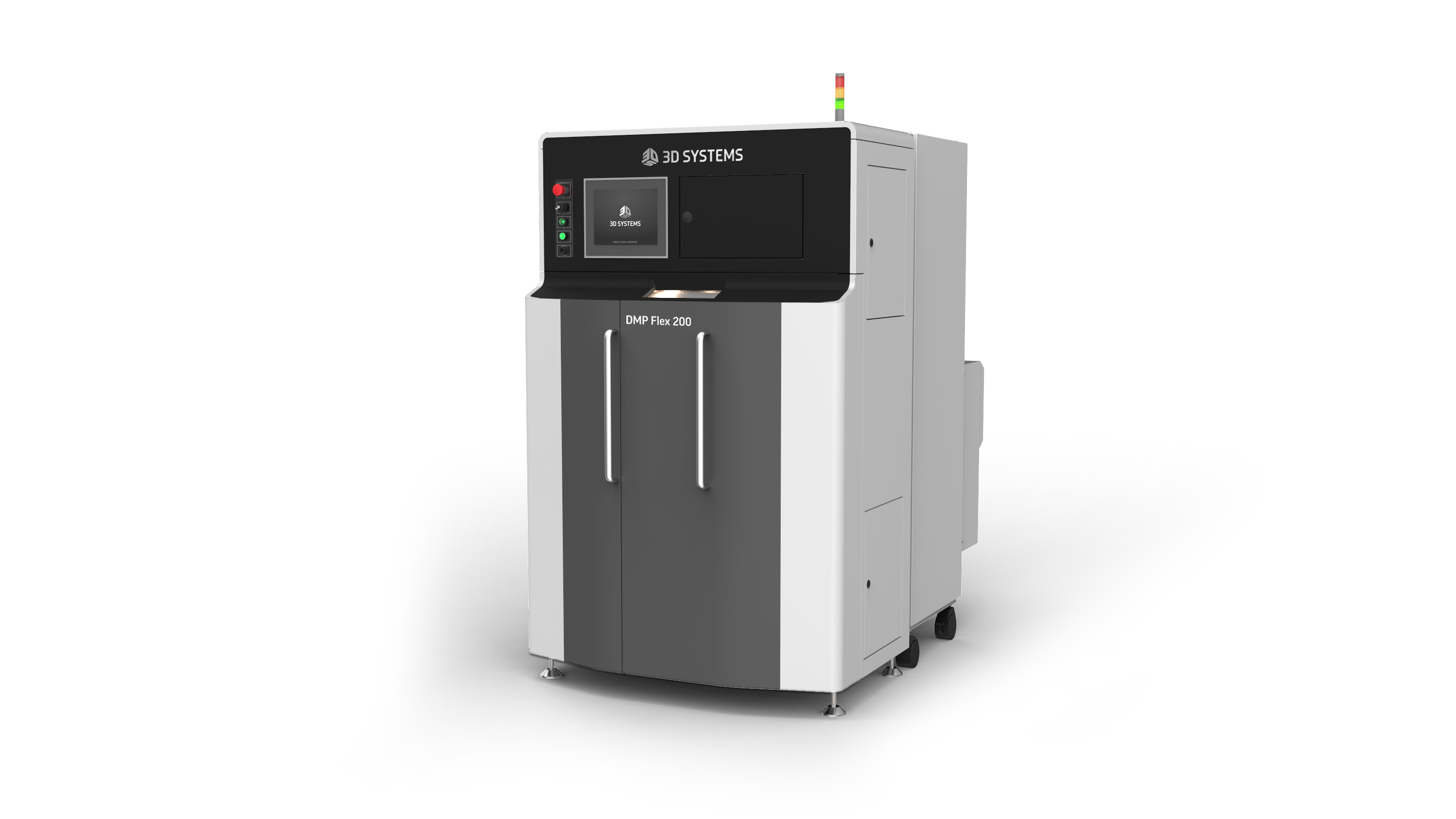

Build volume 140 x 140 x 115 mm

-

High performance at lower cost

-

Easy loading and cleaning

-

Consistent, low O2 environment

Professional and precise metal 3D printer with 500W laser source

-

Build volume 275 x 275 x 420 mm

-

Integrated powder management

-

High throughput, high repeatability

-

Consistent, low O2 environment

Scalable, high quality metal AM with integrated powder management

-

Build volume 275 x 275 x 420 mm

-

High throughput, high repeatability

-

Fast, easy material change

-

Consistent, low O2 environment

Robust, flexible metal 3D printer for rapid part production

-

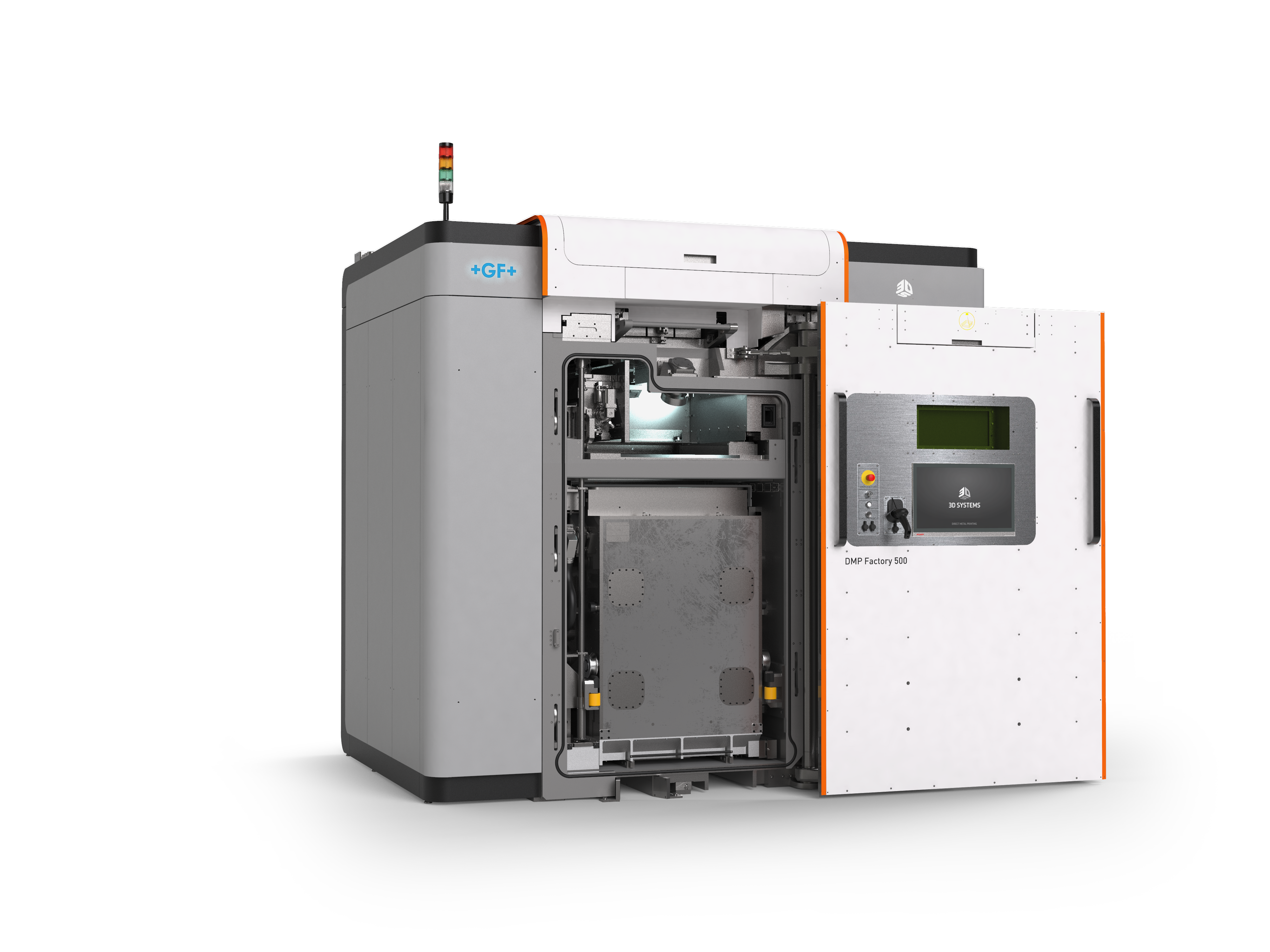

Build volume 500 x 500 x 500 mm

-

Intelligent, seamless part production

-

Consistent, low O2 environment

-

Low TCO for scalable production

Robust, high quality metal AM with integrated powder management

Used for complex parts, often including improved fluid flow in high-temperature and high-strength applications. Metal 3d printing achieves material properties that exceed those of different casting processes. Ideal for gas turbine parts (IGT), exhaust systems, machinery and process industry parts. Available with thoroughly developed and tested print parameters.

Nickel Super Alloy